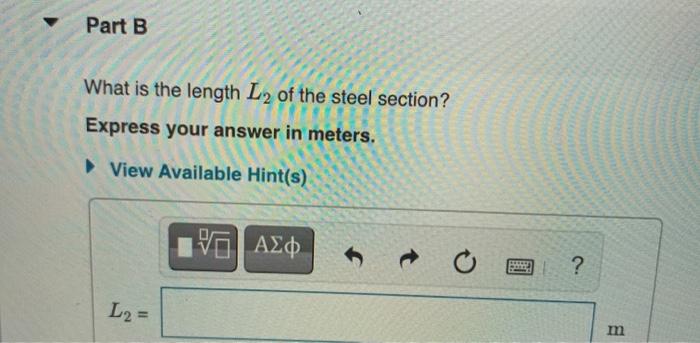

What is the length L2 of the steel section? This seemingly simple question lies at the heart of structural engineering, influencing the design, construction, and performance of countless structures worldwide. Delving into this topic, we will explore the significance of L2, the factors that determine its value, and the methods used to calculate it.

Furthermore, we will examine the impact of L2 on structural performance and provide guidance on selecting appropriate values for different applications.

Understanding the length L2 of a steel section is crucial for ensuring the safety, stability, and efficiency of steel structures. By gaining a comprehensive understanding of this concept, engineers can make informed decisions that contribute to the longevity and reliability of the built environment.

Steel Section Length (L2) Definition: What Is The Length L2 Of The Steel Section

Steel section length (L2) refers to the longitudinal dimension of a steel structural member, typically measured from end to end. It plays a crucial role in determining the structural performance and behavior of the section.

The length of a steel section is a critical factor in design and construction, influencing aspects such as strength, stiffness, stability, and overall structural integrity.

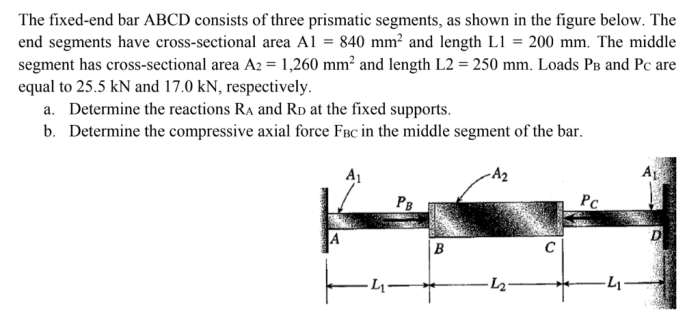

Factors Influencing L2

- Load Type and Magnitude:The type and magnitude of loads acting on the steel section directly affect its required length. Higher loads necessitate longer sections to provide adequate strength and stability.

- Material Properties:The yield strength and elastic modulus of the steel material influence the section’s ability to resist bending and deflection. Higher strength materials allow for shorter sections, while lower strength materials require longer sections.

- Section Shape and Geometry:The shape and geometry of the steel section, such as its cross-sectional area, moment of inertia, and slenderness ratio, determine its structural properties and influence its required length.

- Support Conditions:The type of support conditions at the ends of the steel section, such as pinned, fixed, or continuous, affects the bending moments and shear forces, thereby influencing the required length.

- Design Code Requirements:Building codes and standards specify minimum length requirements for steel sections based on safety and performance considerations.

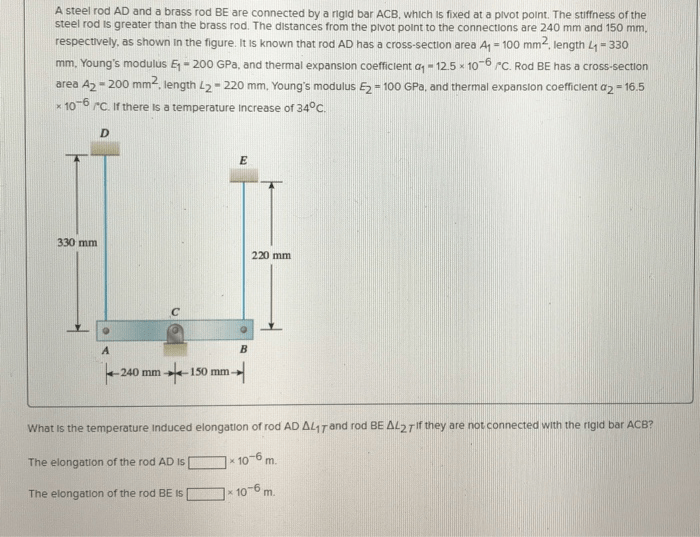

Methods for Determining L2

- Elastic Analysis:This method uses basic engineering principles and assumptions to calculate the length of a steel section based on its material properties, geometry, and load conditions.

- Plastic Analysis:This method considers the plastic behavior of steel and is used for sections subjected to high loads. It involves calculating the collapse load and corresponding length of the section.

- Experimental Testing:Physical testing of steel sections can provide accurate data on their strength and deformation characteristics, which can be used to determine the required length.

- Finite Element Analysis (FEA):FEA is a numerical simulation technique that can model the complex behavior of steel sections under various loading conditions. It provides detailed insights into the stress and strain distribution, allowing for accurate length determination.

Impact of L2 on Structural Performance

- Strength:Longer steel sections generally have higher strength and load-bearing capacity due to their increased material volume.

- Stiffness:Sections with shorter lengths tend to be stiffer and less prone to bending and deflection under loads.

- Stability:Longer sections may experience buckling or instability issues if not adequately supported, especially under compressive loads.

- Ductility:Longer sections typically exhibit better ductility, allowing them to deform plastically without sudden failure.

- Economy:Optimizing the length of steel sections can lead to cost savings while maintaining structural integrity.

Design Considerations for L2

- Strength and Load Resistance:The length of the steel section should be sufficient to resist the anticipated loads and moments without failure.

- Stiffness and Deflection Control:Sections should be designed with appropriate lengths to minimize excessive deflections and ensure structural stability.

- Buckling Prevention:The length of the section should be limited to prevent buckling under compressive loads.

- Ductility and Energy Absorption:In seismic or impact-resistant structures, longer sections may be preferred for enhanced ductility and energy absorption capacity.

- Cost and Optimization:The length of the steel section should be optimized to achieve the required structural performance while minimizing material usage and costs.

Code Requirements for L2, What is the length l2 of the steel section

Building codes and standards, such as the American Institute of Steel Construction (AISC) and the Eurocode 3, provide specific requirements for the minimum length of steel sections in different structural applications.

These codes specify minimum length-to-depth ratios, slenderness limits, and other criteria to ensure the safety and integrity of steel structures.

Quick FAQs

What is the significance of L2 in structural engineering?

L2 plays a crucial role in determining the strength, stiffness, and stability of steel sections. It influences the load-bearing capacity, deflection, and overall structural integrity.

How is L2 determined?

L2 can be calculated using various methods, including empirical formulas, tables, and finite element analysis. The choice of method depends on the complexity of the steel section and the required accuracy.

How does L2 affect the design of steel structures?

L2 is a key consideration in selecting the appropriate steel section for a given application. It influences the overall dimensions, weight, and cost of the structure.

What are the code requirements for L2?

Building codes and standards specify minimum requirements for L2 to ensure the safety and performance of steel structures. These requirements vary depending on the type of structure and the intended use.