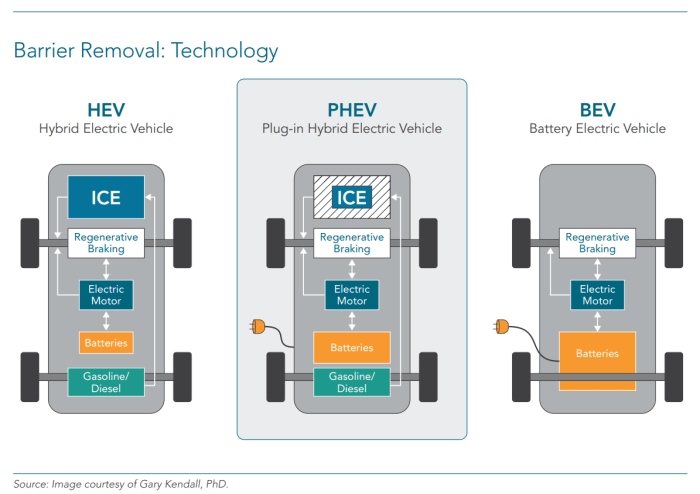

Besides the HEV and EV motor systems themselves, the design, optimization, and integration of these systems into existing vehicle architectures pose significant challenges and opportunities. This article explores the key components influencing motor performance, system integration considerations, design and optimization techniques, and emerging technologies shaping the future of HEV and EV motor systems.

Components Influencing HEV and EV Motor Systems

The performance and efficiency of HEV and EV motor systems are influenced by a range of key components.

Power Electronics

Power electronics play a crucial role in optimizing motor performance by controlling the flow of electricity to and from the motor. Advanced power electronics can improve motor efficiency, reduce torque ripple, and extend motor life.

Battery Technology

The type and capacity of the battery used in HEVs and EVs have a significant impact on motor efficiency. High-energy density batteries allow for more compact and efficient motor systems.

Other Key Components

Other key components that affect motor system performance include:

- Motor windings:The design and materials used for the motor windings influence motor efficiency, power density, and torque output.

- Cooling system:Effective cooling is essential for maintaining motor performance and preventing overheating.

- Sensors:Sensors provide feedback on motor parameters, such as speed, torque, and temperature, which is used to optimize motor control.

System Integration Considerations

Integrating HEV and EV motor systems into existing vehicle architectures presents several challenges.

Challenges

Challenges include:

- Packaging constraints:Finding suitable locations for the motor, power electronics, and battery within the vehicle.

- Weight optimization:Minimizing the weight of the motor system to improve vehicle efficiency and performance.

- System compatibility:Ensuring that the motor system is compatible with the vehicle’s electrical and mechanical systems.

Strategies for Optimization

Strategies for optimizing system integration include:

- Modular design:Breaking the motor system into smaller, interchangeable modules to facilitate packaging and maintenance.

- Lightweight materials:Using lightweight materials, such as aluminum or carbon fiber, to reduce system weight.

- Advanced simulation tools:Using simulation tools to optimize system design and predict performance before physical integration.

Design and Optimization Techniques

Different design approaches can be used for HEV and EV motor systems.

Design Approaches, Besides the hev and ev motor systems themselves

Common design approaches include:

- Permanent magnet motors:Using permanent magnets to create the motor’s magnetic field, resulting in high efficiency and power density.

- Induction motors:Using induced currents to create the motor’s magnetic field, providing high reliability and low maintenance requirements.

- Switched reluctance motors:Using switched reluctance to create the motor’s torque, offering high torque at low speeds and low cost.

Optimization Techniques

Best practices for optimizing motor performance, efficiency, and reliability include:

- Motor sizing:Selecting the appropriate motor size for the specific application to ensure optimal performance and efficiency.

- Cooling optimization:Designing an effective cooling system to maintain motor temperature within acceptable limits.

- Control algorithm optimization:Developing advanced control algorithms to improve motor efficiency and torque response.

Emerging Technologies and Future Trends: Besides The Hev And Ev Motor Systems Themselves

Emerging technologies have the potential to revolutionize HEV and EV motor systems.

Emerging Technologies

Emerging technologies include:

- Wide bandgap semiconductors:Semiconductors with a wider bandgap than traditional silicon, allowing for higher power density and efficiency in power electronics.

- Novel motor topologies:New motor designs that offer improved performance and efficiency, such as axial flux motors and multi-phase motors.

- Advanced battery technologies:Batteries with higher energy density, longer lifespan, and faster charging capabilities.

Challenges and Opportunities

These technologies present challenges and opportunities, such as:

- Cost:The cost of emerging technologies can be a barrier to widespread adoption.

- Reliability:Ensuring the reliability of new technologies is crucial for automotive applications.

- System integration:Integrating emerging technologies into existing vehicle architectures requires careful consideration.

User Queries

What are the key components influencing HEV and EV motor systems?

Power electronics, battery technology, and other components such as cooling systems and sensors play a vital role in optimizing motor performance and efficiency.

How can system integration challenges be addressed in HEV and EV motor systems?

Strategies such as optimizing system efficiency, reducing weight, and carefully integrating the motor systems into existing vehicle architectures are crucial for successful system integration.